Chains and other types of jewelry findings are made from wire. Wire’s strength, flexibility, and inherent beauty make it ideal for designing stunning decorations for pendants or beaded jewelry.

A piece of exquisite wire that has been skillfully wrapped or weaved can also stand on its own. Learn the fundamentals of wire weaving and wrapping, and you’ll quickly be able to make a variety of beautiful wire jewelry.

Selecting Materials For Wire Jewelry

Purchase a set of jewelry cutters and pliers. You will want a pair of wire cutters, round-nosed pliers, and chain-nosed pliers for the majority of basic wire jewelry designs (see also “Wire Wrapping Crystals: How To Make Crystal Jewelry“).

Most craft and hobby stores as well as jewelry and beading supply shops carry these equipment. For precise detail work and creating sharp corners in your wire, flat-edged pliers and bent-nosed pliers are additional helpful tools.

Choose the wire color and material. Gold, silver, or copper are the most popular hues for jewelry wire, but you may also find color wire in every shade imaginable. When choosing a wire type, take in mind that various wire types have various qualities.

Wires made of base metals or alloys, including copper or stainless steel, brass, or nickel silver, are often affordable. If you’re still getting the hang of working with wire, these are wonderful choices.

Three common types of precious metal jewelry wire are silver, gold, and gold-filled. Gold does not tarnish, although sterling silver does. But gold is smoother and simpler to scrape or dent.

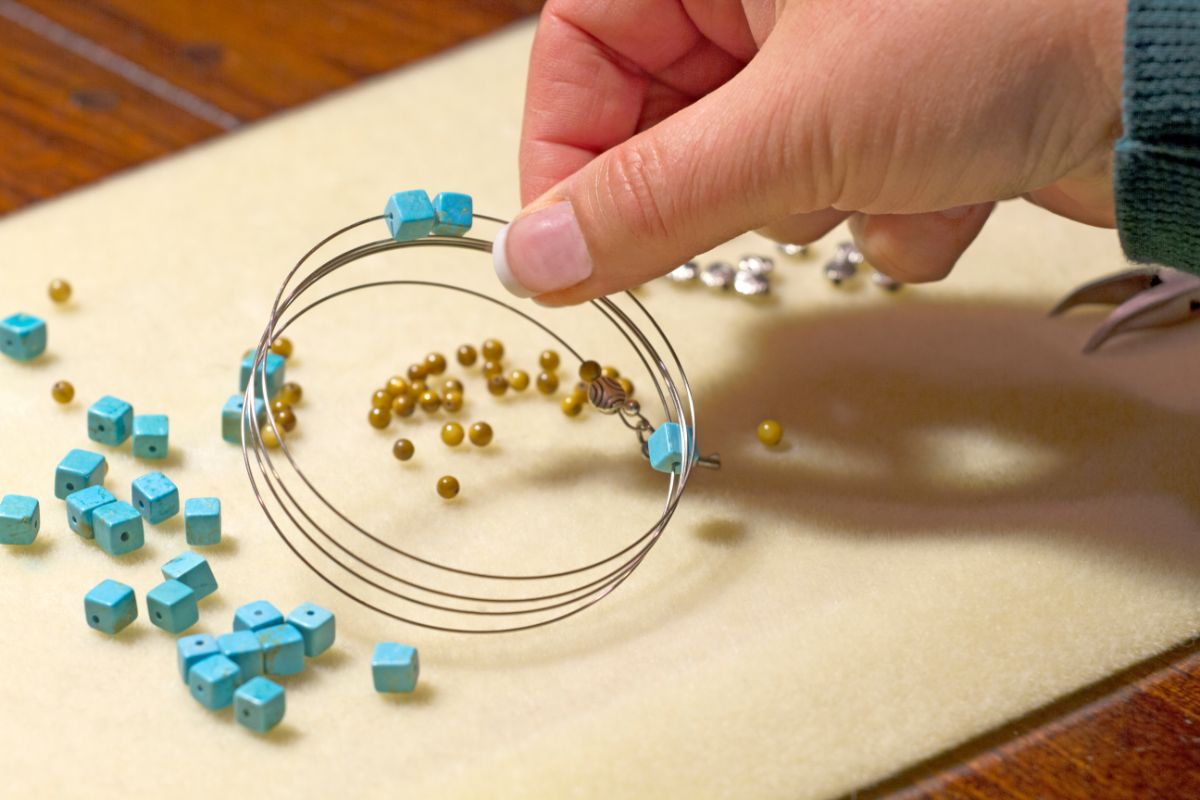

Making simple beaded chokers or bracelets with memory wire is a terrific idea because it keeps its coiled shape. Get wire in a range of gauges. You can require thinner or thicker wire, or a variety of thicknesses, based on the piece you’re building.

The thickness of the wire increases with decreasing wire gauge number. Low-gauge wire works best for tougher components like links and clasps, while high-gauge wire is suitable for intricate coils and weaving.

The best form retention comes from using harder wire. The majority of jewelry wire is available in three different hardness levels: dead soft, semi hard, and fully hard.

Although softer wires do not maintain their form as well as tougher wires, they are more flexible than harder wires.

For delicate tasks requiring a great deal of flexibility, like wire weaving and wire crochet, dead soft wires are recommended. While you work with the wire, it will naturally start to harden.

Dead soft wire may also be used to form really thick wire which would otherwise be challenging to work with into findings or other components.

When you’re finished, you can harden (temper) the completed wire shape by giving it a few quick taps on a steel plate with a rubber mallet. Full hard wires are hard to bend and are easily breakable under excessive stress.

However, it is the greatest at keeping its shape. Half hard wire holds its shape well and is comparatively easy to shape. This type of wire works well to make strong links and load-bearing components.

Purchase premade findings to simplify your work. Components including clasps, connectors, links, and pins are considered jewelry findings. Findings are available in craft or jewelry supply stores.

Pre-made findings can be incorporated into your handmade designs to provide extra flair and facilitate your work.

For instance, by using wire links that have been wrapped, you can attach beads to a readymade chain to create a distinctive necklace. Exquisite wire-wrapped bead earrings look stunning on decorative chandelier earring bases.

Making Wire Jewelry

Step 1

Pick a wire with a medium gauge. Links are load-bearing components, therefore you’ll require a wire that is sufficiently thick to be reasonably durable. Usually, a 20-gauge is a wise choice.

Step 2

With your cutters’ flush side, cut off the end of the wire. To create a flat edge, snip a very small bit from the end of the piece of wire you’re working with.

You should contact the length of wiring you will be dealing with while holding the flat side of the wire clippers. To create your loop, use the flatter end of the wire.

Step 3

With your round-nosed pliers, pinch the wire’s end. Between the sides of your pliers, gently hold the wire’s very tip. Once you look at the pliers in profile, you shouldn’t be able to see the wire end sticking out past the edge of the pliers since the wire ought to be flush with them.

Don’t press the wire too firmly or you risk denting it. Just enough pressure is required to keep the wire in position.

Step 4

Gently roll the wire’s end away from you to create a loop. Tilt your pliers away from you after the wire is firmly in place so that the wire starts to loop around the jaws.

Using your thumb , push the wire against the pliers as you do this. Reposition the pliers inside the loop so you are able to turn them once again once you have rotated your wrist as much as it will allow. Continue doing this until the loop is finished.

Ensure your wire is still roughly at the exact distance from the bottom of your pliers that it was when you began when you adjust the pliers. The loop will be slightly out of form if you don’t.

Step 5

To center the loop, gently rock it backwards with the round-nose pliers. When you’re finished, the wire should be shaped like a “p” when it’s wrapped around the pliers’ jaw.

Place a jaw into the loop and carefully compress the wire at the bottom of the loop to center it over the wire’s end.

Utilizing your free hand to hold the wire firmly at the bottom of the loop, bend it back slightly with the pliers so the loop is centered along the wire’s length much like the dot of a “i.”

Step 6

To seal the loop, using your chain-nose pliers. There can be a tiny space between the loop’s end and the remaining wire after you’ve finished the loop.

Take hold of the loop’s end with the chain-nose pliers and press it in while moving it back and forth until the space is closed. A squashed loop will result if you attempt to push the edges of the loop in from the outside.

Step 7

Use the cutters to cut off any extra tail after you’re finished. With the chain-nose pliers or using fingernails, gently squeeze the wrap to make it tighter.

When there are already beads on the wire, using this approach is most straightforward. When making the 90° bend, hold the wire immediately above the bead.

As a result, there will be a small gap between the beads and the loop where the tail can be wrapped. Once it is finished, you won’t be capable of opening this loop, therefore you must attach it to something you can open, like a jump ring or a basic loop.

Step 8

If you’d like, you can thread a few beads onto the wire. You could place a bead into the wire and create another loop on the opposite side.

You can string numerous beads together in this manner. Another option is to thread the bead onto a head pin with a flat end and create a loop just above your bead. The bead can then be attached to a chain, ear hook, or bracelet as a charm.

Final Thoughts

We hope you’ve enjoyed this guide on how to make your own wire jewelry. With a few basic supplies and by following these simple steps, you can make your own jewelry from the comfort of your own home.

- Master Crochet Stitches for Cozy Creations - January 23, 2024

- Half Double Crochet Guide for Cozy Creations - January 23, 2024

- Elevate Your Space with Unique Macrame Creations - January 23, 2024